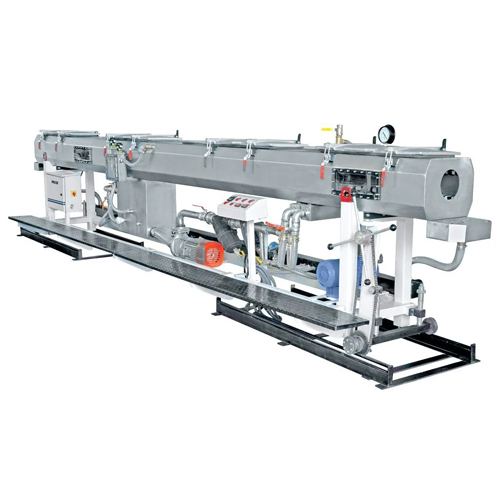

Twin Screw Extruder Machine

Twin Screw Extruder Machine Specification

- Type

- Plastic Extrusion Machine Twin Screw (Co-Rotating, Conical / Parallel)

- Material

- Mild steel, Stainless steel, En41B

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Direct

- Screw Diameter

- 51 Millimeter (mm)

- Power

- 415 Volt (v)

- Warranty

- 12 months

Twin Screw Extruder Machine Trade Information

- Minimum Order Quantity

- 1 Number

- FOB Port

- India

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Per Month

- Delivery Time

- 2-10 Days

- Packaging Details

- Packaging Type: Export-grade protective packaging Heavy-duty wooden crates or pallets Moisture-proof wrapping with industrial plastic film Shock-absorbent padding for delicate components Included in Packaging: Main Extruder Unit Control Panel Die Head & Attachments Tool Kit & Maintenance Manual Safety and Operation Instructions Spare Parts Kit (standard) Protection Measures: Anti-corrosion coating on metallic surfaces Desiccants included to prevent moisture damage Secured strapping for transport stability

- Main Export Market(s)

- Asia, South America, Middle East, Africa

- Main Domestic Market

- West Bengal, Kerala, Odisha, Maharashtra, Pondicherry, Madhya Pradesh, Telangana, Andhra Pradesh, Tamil Nadu, Arunachal Pradesh, Karnataka

- Certifications

- ISO 9001:2015

About Twin Screw Extruder Machine

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in PVC Pipe Making Machine Category

Vacuum Sizing Tank

Price 450000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Material : Mild steel

Drive Type : Other

Type : Sizing Tank

Pvc Conduit Pipe Making Machine

Price 1950000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Material : Mild steel

Drive Type : Other

Type : Pipe Machine

Hdpe Pipe Making Machine

Price 3500000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Material : Mild steel

Drive Type : Other

Type : Pipe Machine

Pvc Garden Pipe Machine

Price 1650000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Material : Mild steel

Drive Type : Other

Type : Pipe Machine

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free