Pvc Conduit Pipe Making Machine

Pvc Conduit Pipe Making Machine Specification

- Type

- Pipe Machine

- Material

- Mild steel

- Capacity

- 1000 Kg/hr

- Automatic Grade

- Automatic

- Control System

- Human Machine Interface

- Drive Type

- Other

- Screw Diameter

- 20 mm to 120 mm Millimeter (mm)

Pvc Conduit Pipe Making Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- India

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

- Sample Available

- No

- Packaging Details

- Packaging Type: Modular packaging: Each unit (extruder, die head, vacuum tank, caterpuller, cutter, and tipping unit) is packed separately Heavy-duty wooden crates and pallets for secure handling and shipping Plastic wrapping and foam padding for protection against moisture, dust, and physical impact Steel strapping and internal bracing to prevent movement during transit Protection Measures: Anti-rust oil coating on all metallic parts

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- Andhra Pradesh, West Bengal, Kerala, Assam, Telangana, Maharashtra, Arunachal Pradesh, Odisha, Madhya Pradesh, Karnataka, Pondicherry, Tamil Nadu

- Certifications

- ISO 9001:2015

About Pvc Conduit Pipe Making Machine

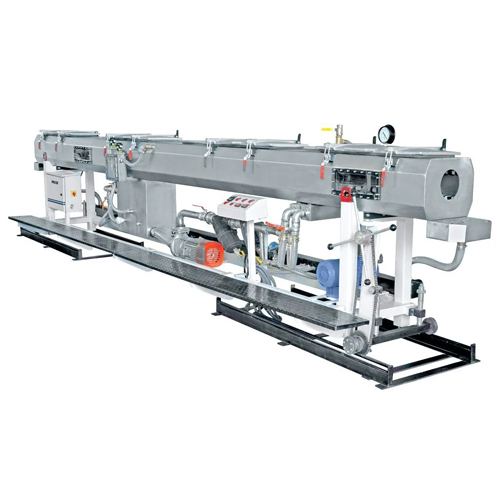

PVC Conduit Pipe Making Machine

Brand: Plastivo Extrusions

Technical Specifications

-

Capacity: Up to 1000 kg/hr

-

Automation Grade: Automatic

-

Power Consumption: 50 75 kW (model-dependent)

-

Material: Stainless Steel & High-Quality Alloys

-

Screw Diameter: 20 mm to 120 mm

-

Pipe Size Range: 16 mm to 63 mm diameter

-

Heating Zones: 4 to 6 zones for precise barrel temperature control

-

Cooling System: Includes vacuum cooling tanks and water spray system

-

Control System: PLC-controlled with real-time process monitoring

Product Overview

The PVC Conduit Pipe Making Machine by Plastivo Extrusions is a high-output, precision-engineered extrusion system designed for manufacturing PVC conduit pipes used in electrical wiring and plumbing applications. Built for continuous operation, the machine integrates a robust cooling system, advanced PLC control, and a reliable screw-barrel setup to ensure smooth production with consistent pipe quality.

Its automatic functionality and modular configurations make it suitable for medium to large-scale manufacturers looking to scale operations without compromising quality or energy efficiency.

Key Features

-

High Output: Supports continuous production up to 1000 kg/hr

-

Advanced Automation: Fully automatic setup for streamlined operations

-

Precision Control: 46 heating zones for barrel temperature accuracy

-

Custom Configurations: Supports pipe diameters from 16 mm to 63 mm

-

Efficient Cooling: Integrated vacuum and water spray systems for pipe stability

-

Durable Construction: Made with stainless steel and high-quality alloys for longevity

-

Smart Interface: PLC system enables real-time monitoring and control

Why Choose Plastivos PVC Conduit Pipe Making Machine?

Consistent Quality: Delivers smooth and dimensionally accurate conduit pipes

Energy Efficient: Low power consumption relative to output

Versatile Applications: Ideal for electrical, plumbing, and industrial conduit pipe production

User-Friendly: Easy-to-use PLC controls and intuitive interface

Long-Term Reliability: Engineered for durability, reduced maintenance, and high uptime

FAQs PVC Conduit Pipe Making Machine

Q1: What pipe sizes can the machine produce?

A: The machine is capable of producing PVC conduit pipes from 16 mm to 63 mm in diameter.

Q2: What is the maximum output capacity?

A: It can produce up to 1000 kg/hr, depending on the model and settings.

Q3: Is the machine fully automatic?

A: Yes, it is designed for automatic operation, reducing manual involvement and increasing efficiency.

Q4: What kind of materials is the machine built with?

A: The structure is made from stainless steel and high-quality wear-resistant alloys for long service life.

Q5: How is the cooling of pipes handled?

A: The machine includes a vacuum cooling tank and water sprays, ensuring uniform and rapid pipe cooling.

Q6: Can I monitor and adjust parameters during production?

A: Yes, the PLC-based control system allows real-time monitoring and adjustments for all major parameters.

Q7: Is it suitable for both electrical and plumbing conduit pipe applications?

A: Absolutely. It is designed to produce high-quality conduit pipes for electrical wiring, plumbing systems, and more.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PVC Pipe Making Machine Category

Twin Screw Extruder Machine

Price 1450000.0 INR / Unit

Minimum Order Quantity : 1 Number

Type : Plastic Extrusion Machine Twin Screw (CoRotating, Conical / Parallel)

Material : Other

Automatic Grade : Automatic

Drive Type : Direct

Vacuum Sizing Tank

Price 450000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Sizing Tank

Material : Mild steel

Automatic Grade : Automatic

Drive Type : Other

Hdpe Pipe Making Machine

Price 3500000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Pipe Machine

Material : Mild steel

Automatic Grade : Automatic

Drive Type : Other

Pvc Garden Pipe Machine

Price 1650000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Pipe Machine

Material : Mild steel

Automatic Grade : Automatic

Drive Type : Other

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free