Hdpe Pipe Making Machine

Hdpe Pipe Making Machine Specification

- Type

- Pipe Machine

- Material

- Mild steel

- Capacity

- 800 Kg/hr

- Automatic Grade

- Automatic

- Drive Type

- Other

- Screw Diameter

- 25 mm to 150 mm Millimeter (mm)

Hdpe Pipe Making Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- India

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

- Sample Available

- No

- Packaging Details

- Packaging Type: Modular packaging for all units (extruder, die head, cooling tanks, haul-off unit, cutter) Packed in ISPM-15 certified wooden crates or palletized loads Wrapped in plastic film, with foam and edge protection for sensitive areas Secured with steel strapping and bracing for safe transit Protection Measures: Rust-preventive oil on metal parts

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- Kerala, Assam, Telangana, Andhra Pradesh, West Bengal, Madhya Pradesh, Tamil Nadu, Pondicherry, Karnataka, Maharashtra, Odisha, Arunachal Pradesh

- Certifications

- ISO 9001:2015

About Hdpe Pipe Making Machine

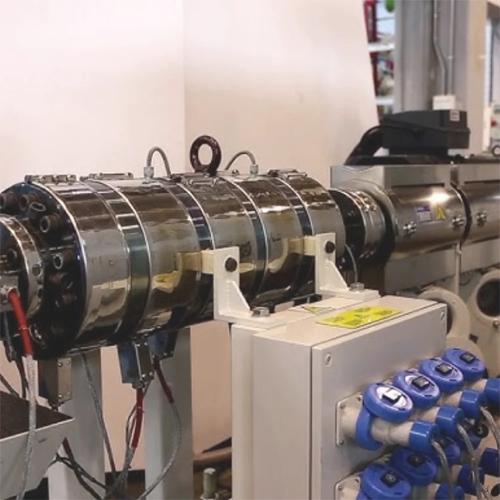

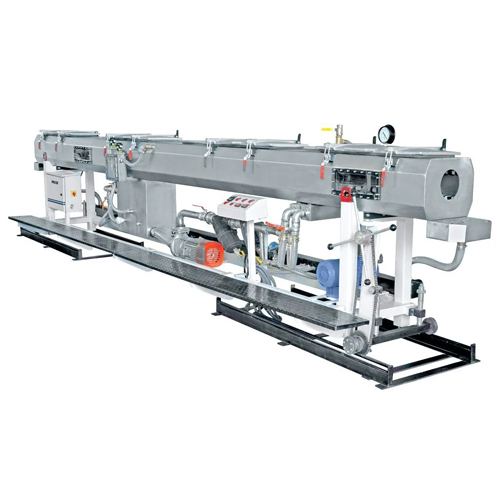

HDPE Pipe Making Machine

Brand: Plastivo Extrusions

Technical Specifications

-

Capacity: Up to 800 kg/hr

-

Power Consumption: 50150 kW (based on configuration)

-

Machine Type: Automatic

-

Pipe Diameter Range: 20 mm to 450 mm

-

Screw Diameter: 25 mm to 150 mm

-

Heating Zones: 4 to 8 zones for precise barrel temperature control

-

Control System: PLC-based system with real-time monitoring and automation

-

Cooling System: Vacuum cooling tanks and water spray systems for uniform pipe cooling

Product Overview

The HDPE Pipe Making Machine by Plastivo Extrusions is a high-performance extrusion system engineered to produce HDPE pipes of various diameters for applications in water supply, gas distribution, agriculture, and drainage. Built with precision controls, high-quality components, and an intuitive PLC system, it guarantees consistent pipe dimensions, efficient energy use, and minimal operational downtime.

Designed for heavy-duty industrial environments, this machine supports large-diameter pipe production and long runs without compromising quality.

Key Features

-

High Output: Supports continuous production up to 800 kg/hr

-

Full Automation: PLC-controlled for seamless operation and real-time parameter control

-

Durable Materials: Made with stainless steel and industrial-grade alloys

-

Custom Configurations: Pipe diameters from 20 mm to 450 mm supported

-

Precision Heating: 48 independently controlled zones ensure consistent melt flow

-

Advanced Cooling: Vacuum and water spray cooling tanks ensure stable pipe formation

Why Choose Plastivos HDPE Pipe Making Machine?

-

Precision Manufacturing: Delivers uniform pipe wall thickness and smooth surface finish

-

Energy Efficient: Lower power use across a broad capacity range

-

Wide Application: Ideal for water, gas, sewage, and agriculture pipe production

-

User-Friendly Interface: Simple PLC control with live monitoring

-

Heavy-Duty Reliability: Engineered for continuous operation with low maintenance

FAQs HDPE Pipe Making Machine

Q1: What pipe diameters can this machine produce?

A: It supports HDPE pipe production from 20 mm to 450 mm in diameter.

Q2: How much output does it offer per hour?

A: The machine offers an output of up to 800 kg/hr, depending on screw size and material.

Q3: Is it fully automatic?

A: Yes, its a fully automatic system with a PLC-based control panel and real-time monitoring.

Q4: How many heating zones are included?

A: Depending on configuration, the machine includes 4 to 8 heating zones for optimal melt control.

Q5: What is the cooling system like?

A: It includes vacuum cooling tanks and water spray units for fast and uniform pipe cooling.

Q6: What power range is required?

A: It consumes between 50 kW and 150 kW, based on model and production load.

Q7: What industries can use this machine?

A: Its suitable for water infrastructure, gas distribution, drainage systems, and agricultural piping.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PVC Pipe Making Machine Category

Twin Screw Extruder Machine

Price 1450000.0 INR / Unit

Minimum Order Quantity : 1 Number

Automatic Grade : Automatic

Drive Type : Direct

Type : Plastic Extrusion Machine Twin Screw (CoRotating, Conical / Parallel)

Material : Other

Pvc Conduit Pipe Making Machine

Price 1950000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Drive Type : Other

Type : Pipe Machine

Material : Mild steel

Vacuum Sizing Tank

Price 450000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Drive Type : Other

Type : Sizing Tank

Material : Mild steel

Pvc Garden Pipe Machine

Price 1650000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Drive Type : Other

Type : Pipe Machine

Material : Mild steel

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free