Plastic Dana Machine With Die Face Cutter

Plastic Dana Machine With Die Face Cutter Specification

- Type

- Dana Machine

- Material

- Mild steel

- Capacity

- 100-800 Kg/hr

- Automatic Grade

- Automatic

- Control System

- Human Machine Interface

- Drive Type

- Other

Plastic Dana Machine With Die Face Cutter Trade Information

- Minimum Order Quantity

- 1 Number

- FOB Port

- India

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 5 Per Month

- Delivery Time

- 30 Days

- Sample Available

- No

- Packaging Details

- Packaging Type: Heavy-duty wooden crate with industrial-grade moisture-proof wrapping Protection Measures: Plastic film wrapping for moisture and dust resistance Rust-preventive coating on metal surfaces Shock-absorbing pads and internal supports for transport stability Steel strapping to prevent shifting during handling

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- Madhya Pradesh, Tamil Nadu, West Bengal, Karnataka, Telangana, Odisha, Kerala, Andhra Pradesh, Arunachal Pradesh, Assam, Maharashtra, Pondicherry

- Certifications

- ISO 9001:2015

About Plastic Dana Machine With Die Face Cutter

Plastic Dana Machine with Die Face Cutter

Brand: Plastivo Extrusions

Technical Specifications

-

Production Capacity: 500 kg/hr

-

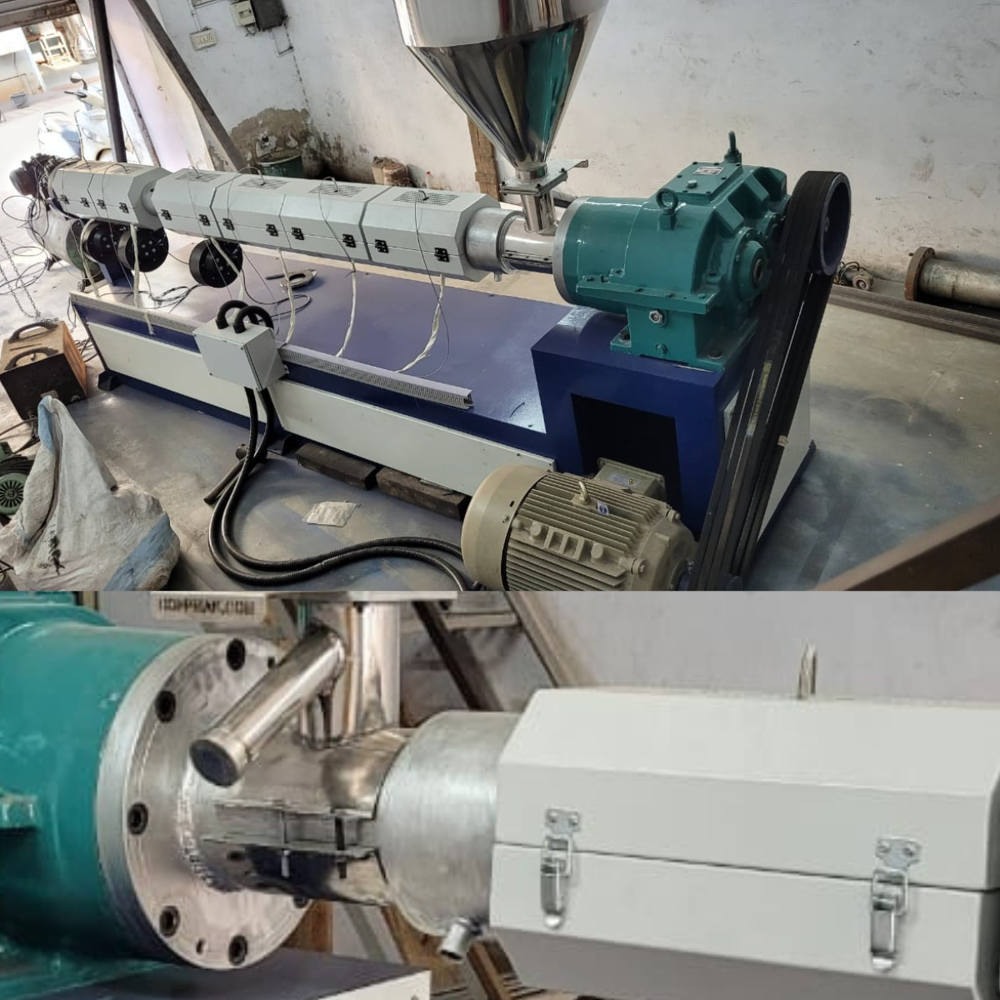

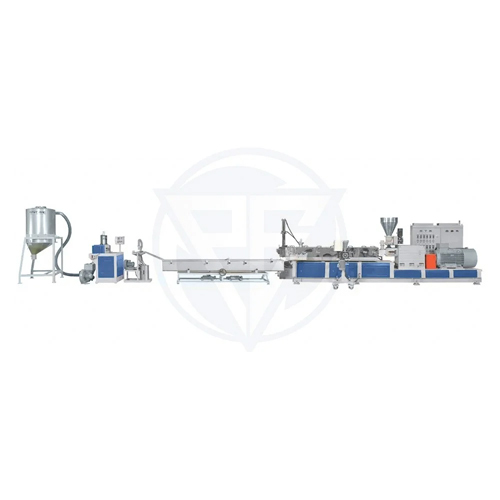

Type of Machine: Plastic Dana Making Machine

-

Capacity Range: 100 800 kg/hr

-

Power Consumption: 50 100 kW

-

Usage/Application: Plastic Recycling

-

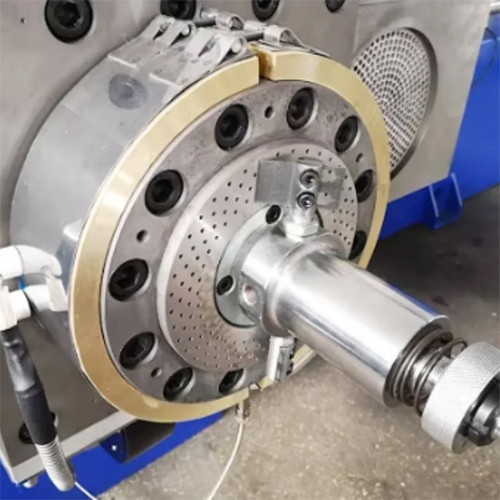

Cutting Technology: Die Face Cutting for precision and efficiency

-

Control System: PLC-based system with real-time monitoring

-

Pellet Size: Adjustable for various applications

-

Cooling System: Integrated water cooling for die and granules

Product Overview

The Plastic Dana Machine with Die Face Cutter by Plastivo Extrusions is a high-performance granulation solution built for the efficient recycling of plastic waste into uniform plastic pellets (dana). With a focus on precision, durability, and energy efficiency, this machine is ideal for continuous production in industrial recycling and compounding setups.

Key Features

-

High Efficiency: Continuous operation with minimal downtime for maximum productivity

-

Die Face Cutter: Advanced cutting system for consistent granule size and smooth pellet surface

-

Durable Build: Manufactured using high-grade materials for long-term performance

-

Fully Automatic: PLC-based automation ensures seamless control and reduces labor dependence

-

Integrated Cooling System: Water-cooled die and granules for enhanced process stability

Why Choose Plastivo's Plastic Dana Machine?

-

Precision Granulation: Produces uniform, high-quality granules ready for downstream processing

-

Energy-Efficient Operation: Optimized to deliver high output while keeping energy usage in check

-

Wide Material Compatibility: Handles PP, HDPE, LDPE, PET, and other thermoplastics with ease

-

Rugged Design: Built to withstand high workloads and harsh production environments

-

User-Friendly System: Easy to operate, maintain, and monitor with minimal training

FAQs Plastic Dana Machine with Die Face Cutter

Q1: What types of plastic can this machine process?

A: It can process a wide range of thermoplastics including PP, HDPE, LDPE, PET, and similar materials.

Q2: Is the pellet size adjustable?

A: Yes, the pellet size is adjustable to meet different application requirements.

Q3: What is die-face cutting and why is it better?

A: Die-face cutting allows precise, uniform pellet formation directly at the die, reducing waste and improving consistency.

Q4: How much power does the machine consume?

A: Power consumption ranges from 50 kW to 100 kW, depending on the model and production capacity.

Q5: Is it fully automatic?

A: Yes, it features a fully automatic PLC-based control system for ease of operation and minimal manual intervention.

Q6: Does it include a cooling system?

A: Yes, the machine comes with an integrated water cooling system for both the die and the produced granules.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plastic Granules Making Machine Category

Single Screw Extruder Machines

Price 1100000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Capacity : Upto 450 Kg/hr

Material : Other

Type : Single Screw Extruder Machines

Automatic Grade : SemiAutomatic

Plastic Strand Pelletizer Machine

Price 1300000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 500 Kg/hr

Material : Mild steel

Type : Pelletizer Machine

Automatic Grade : Automatic

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free